1.Introduction to AC Drives (Variable Frequency Drives) In the realm of modern industrial control an......

READ MOREWhat factors should I consider when sizing a servo motor?

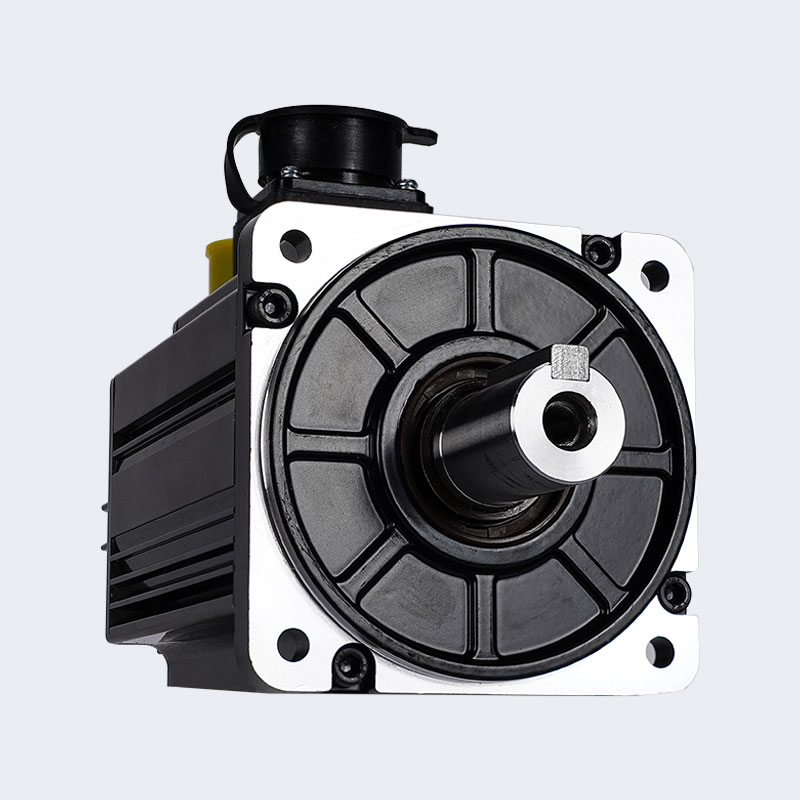

Sizing an industrial servo motor is a critical step in any motion control system design. Getting it wrong can lead to poor performance, frequent failures, or unnecessary costs. Instead of just picking a motor based on a general horsepower rating, a professional approach involves a detailed analysis of your application's specific requirements.

To properly size a servo motor, you must consider the following key factors.

1. Motion Profile Analysis

The first step is to define the required motion. A motion profile breaks down a single movement cycle into segments of acceleration, constant velocity, and deceleration.

-

Acceleration and Deceleration Time: This determines the peak torque required to start and stop the load. Faster ramps demand higher torque.

-

Constant Velocity Time: The motor needs to provide a certain level of continuous torque to overcome friction and other forces during the steady-state part of the move.

-

Dwell Time: The time between motion cycles is crucial for allowing the motor to cool down. It affects the motor's ability to handle the next cycle's demands.

2. Load and Inertia

A motor’s ability to move a load is directly tied to the inertia of the system. Inertia is a measure of an object's resistance to a change in motion.

-

Load Inertia: This is the inertia of everything the motor needs to move, including the load itself, gears, pulleys, and any other mechanical components.

-

Motor Inertia: This is the inertia of the motor's rotor. The ideal scenario is for the motor inertia to be a small fraction of the total system inertia. A good rule of thumb is to have a load-to-motor inertia ratio between 3:1 and 5:1, though ratios up to 10:1 can be acceptable with proper tuning. Mismatched inertia can cause unstable or difficult-to-tune control loops, leading to vibrations and poor positioning accuracy.

3. Torque Requirements

Torque is the rotational force produced by the motor. You need to consider two types of torque:

-

Continuous Torque (

This is the maximum torque the motor can produce continuously without overheating. It's needed for overcoming steady-state forces like friction and gravity. It is the average torque over a complete duty cycle.

-

Peak Torque (

This is the maximum torque the motor can deliver for a short duration, typically during acceleration or deceleration. The motor's peak torque must be higher than your application's maximum acceleration torque to ensure dynamic performance.

You can use the root mean square (RMS) method to calculate the required continuous torque, taking into account the torque levels and durations for each segment of the motion profile. The calculated RMS torque must be less than the motor's rated continuous torque (). Similarly, the required peak torque must be less than the motor's rated peak torque ().

4. Speed Requirements

The motor’s speed rating is another critical factor. The chosen motor must be capable of reaching the maximum speed required by your motion profile. You should also consider the speed-torque curve of the motor. As the speed increases, the available torque often decreases. Make sure the motor can provide the necessary torque at the required speed.

5. Environmental Factors

An industrial servo motor needs to withstand the conditions of its operating environment.

-

Temperature: Ensure the motor’s operating temperature range is suitable for the environment. High ambient temperatures can derate the motor's performance.

-

Ingress Protection (IP) Rating: This rating indicates the motor's resistance to dust and liquids. For dusty or wet environments, a higher IP rating is essential to prevent motor damage.

-

Vibration and Shock: The motor should be mechanically robust enough to handle any vibrations or shocks present in the application.

By carefully considering each of these factors—motion profile, inertia, torque, speed, and environment—you can select an industrial servo motor that delivers optimal performance, efficiency, and longevity for your specific application. A thorough sizing process not only ensures reliable operation but also helps you avoid oversizing, which can lead to higher costs and wasted energy.

English

English Español

Español عربى

عربى