Chemical Industry

Learn more

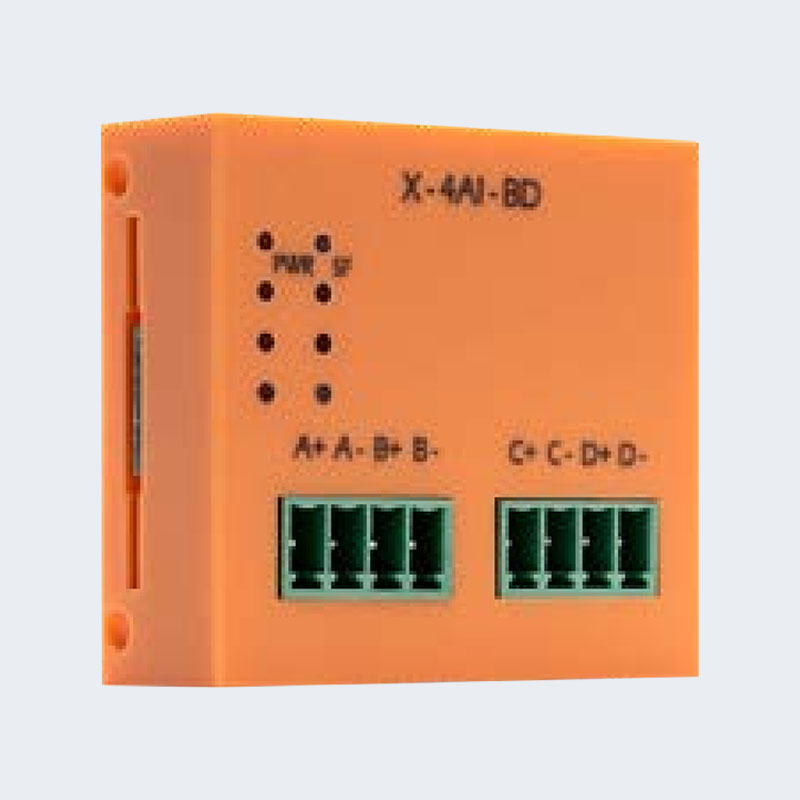

• Rich interfaces

• Strong expansion capability

• Powerful motion control function

• Strong axis control capability

• Fast calculation speed

• Small and regular shape

Raynen Technology was founded in 2007 and listed on the Shanghai Stock Exchange in 2017 (stock code: 603933). It is a high-tech enterprise specializing in the research and development, production, sales and service of industrial automation products.

As China Programmable Logic Controller (PLC) Manufacturers and Programmable Logic Controller (PLC) Factory, the company is headquartered in Fuzhou and has nearly 20 subsidiaries. It has set up R&D centers in Shanghai, Wuhan, Fuzhou and Changzhou. The company insists on driving the development of technology and products with scientific and technological innovation. Through years of precipitation, it has formed a group of reputable domestic companies. Core technology and patented technology.

As a reputable supplier of industrial automatic control products in China, Raynen Technology focuses on the research of control and drive technology. After years of product and technology cultivation, it has completed a comprehensive expansion from industry-specific electronic control systems to general automation products. The company has core products such as AC servo systems, frequency converters, programmable controllers, human-machine interfaces, and Internet of Things gateways, which are widely used in electronics, textile machinery, machine tools, printing and packaging machinery, logistics equipment, intelligent manipulators, woodworking machinery, and laser processing In the fields of equipment, metallurgy, petroleum, chemical industry, etc., we use reputable technology to provide equipment manufacturing enterprises with competitive products and personalized solutions. We offer Custom Programmable Logic Controller (PLC).

Raynen Technology has always been committed to becoming a international supplier of intelligent industrial automation products and solutions to achieve the common growth of corporate value and customer value.

Established In

Employees

Export Country

Design Right Patent

Introduction to Programmable Logic Controllers (PLCs) Programmable Logic Controllers (PLCs) are specialized industrial computers designed to automate machinery ...

Understanding Medium-Voltage Soft Starters Medium-voltage soft starters are advanced electrical devices designed to regulate the acceleration and deceleration o...

Core Working Principles of Medium-Voltage Soft Starters Medium-Voltage (MV) soft starters are engineered to manage the startup of high-capacity AC motors, typic...

Understanding the Core Mechanics of Low Voltage Variable Frequency Drives A Low Voltage Variable Frequency Drive (VFD) is a sophisticated power electronics devi...

Unlocking the Power of PLCs: Rich Interfaces and Strong Expansion Capabilities

Programmable Logic Controllers (PLCs) are essential in modern industrial automation, serving as the intelligent core that orchestrates complex machinery and control systems. As manufacturing environments continue to evolve toward higher precision, greater flexibility, and real-time responsiveness, the demand for PLCs that offer rich interfaces and strong expansion capabilities has grown significantly. These two features are now central to how manufacturers adapt to rapidly changing production requirements and implement smarter, more connected systems.

The latest generation of PLCs has moved far beyond simple control tasks. With multiple built-in communication ports, I/O options, and protocol compatibility, PLCs now serve as the backbone for integrated automation. Rich interface support allows seamless communication with sensors, actuators, servo systems, and upper-layer management systems such as SCADA or MES. This connectivity is essential for maintaining efficient production workflows, especially in environments where diverse devices must work in coordination.

Equally important is the ability to expand system capabilities as production needs grow. Strong expansion capability ensures that a single Programmable Logic Controller platform can evolve with an application, whether it involves adding new axes for motion control or integrating more I/O modules for additional monitoring points. This flexibility helps reduce downtime, lowers hardware investment over time, and supports a modular approach to system design.

In response to these industrial demands, innovative automation companies have introduced PLCs with high-speed processors, compact form factors, and powerful motion control functions. One prominent manufacturer, headquartered in Fuzhou with a nationwide network of R&D centers, has emerged as a leader in China’s industrial automation sector. With over a decade of experience and a growing global footprint, the company has continuously refined its PLC offerings to meet the needs of industries such as textile machinery, logistics, printing, laser processing, and chemical production.

This company’s approach to PLC development emphasizes not only performance but also adaptability. By incorporating electronic design modularity, high-speed calculation, and multi-axis control capabilities into a compact housing, its PLCs provide a competitive edge for equipment manufacturers seeking space-saving solutions without compromising functionality. These controllers are capable of handling both general automation tasks and demanding motion control requirements, making them suitable for a broad spectrum of industrial scenarios.

Over the years, the company has broadened its scope from specialized electronic control systems to a full lineup of automation products. Its portfolio now includes AC servo drives, frequency inverters, human-machine interfaces, and industrial IoT gateways, offering complete automation solutions to end users and OEMs alike. With a focus on innovation-driven development and a commitment to delivering tailored solutions, the company supports its clients in enhancing operational efficiency and reducing integration complexity.

The ability to customize PLCs for different applications is another reason why this manufacturer continues to gain recognition. Whether it’s a high-speed packaging line requiring precise motion synchronization or a chemical plant demanding scalable control systems, the PLCs can be configured to deliver optimal performance across diverse industrial conditions.

As automation continues to shape the future of manufacturing, PLCs with rich interfaces and scalable architecture are becoming the standard, not the exception. Manufacturers looking to future-proof their operations must consider controllers that combine processing power, communication flexibility, and modular design. By adopting solutions from companies that prioritize technological advancement and long-term customer value, industrial enterprises can better navigate the challenges of Industry 4.0 and beyond.

PLCs are no longer just the hidden controllers in a panel—they are the enablers of intelligent production. With enhanced connectivity and expansion readiness, they empower industries to stay agile, competitive, and aligned with digital transformation goals.